Engineering in the nuclear industry

sections

One of the most important systems of research nuclear reactors, which determine its neutronic characteristics, safety and cost, are systems that ensure reliable heat removal from the core in all modes. With the increase in safety requirements for nuclear installations after serious accidents at nuclear power plants, the complexity and branching of both safety systems and normal operation systems has significantly increased. This led to a sharp increase in the number of possible failures of elements leading to emergency situations and an increase in the complexity of analysis to justify the safety of the installation.

The creation of simple, safe and reliable research reactor facilities with good performance depends to a large extent on the optimization of heat removal systems from the reactor cores. The design of such installations, taking into account adverse terrain factors (seismicity, lack of reliable power supply systems, etc.), must take into account the likelihood of failure of any security systems, as well as human errors or even malicious acts, for example, by terrorists.

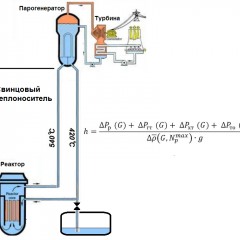

When designing reactors, it is necessary to strive to ensure that the core always remains in the water, and the natural circulation of the coolant through the core ensures safe heat removal from the fuel elements, ensuring the integrity of the first and second barriers — the fuel matrix and cladding.

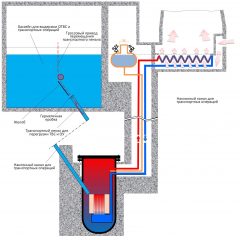

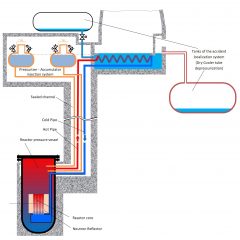

The simplest and most reliable way to fulfill this requirement is to place the core directly in the pool (tank) of the reactor, or to place the reactor vessel in the pool, which makes it possible in emergency situations to organize a natural circulation circuit of the pool water through the core.

I believe that the potential of using natural circulation in reactor plants is greatly underestimated and the following examples highlight these possibilities.

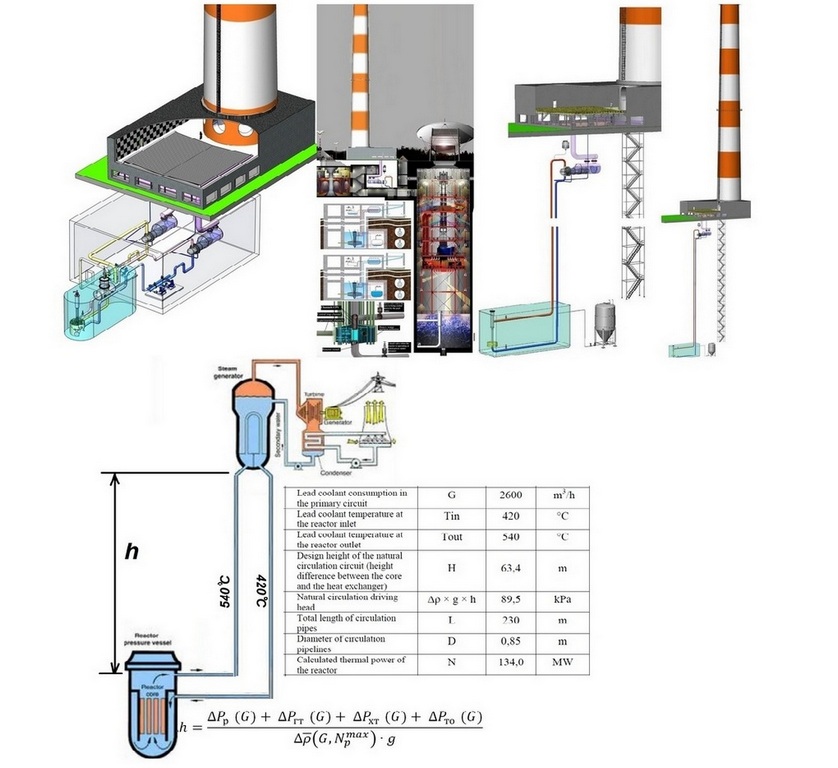

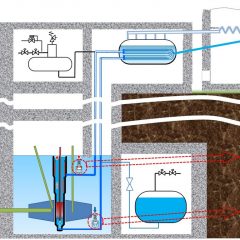

Perhaps the key element that psychologically constrains consideration of the design of reactor plants of medium and large power, which determines the requirements for a significant height of the natural circulation loop, is the need to locate them deep underground and the seeming high economic costs. However, if we take into account the entire cycle — from construction to dismantling, it turns out that the problems with the decommissioning of such installations of such installations are disproportionately less than with conventional design.

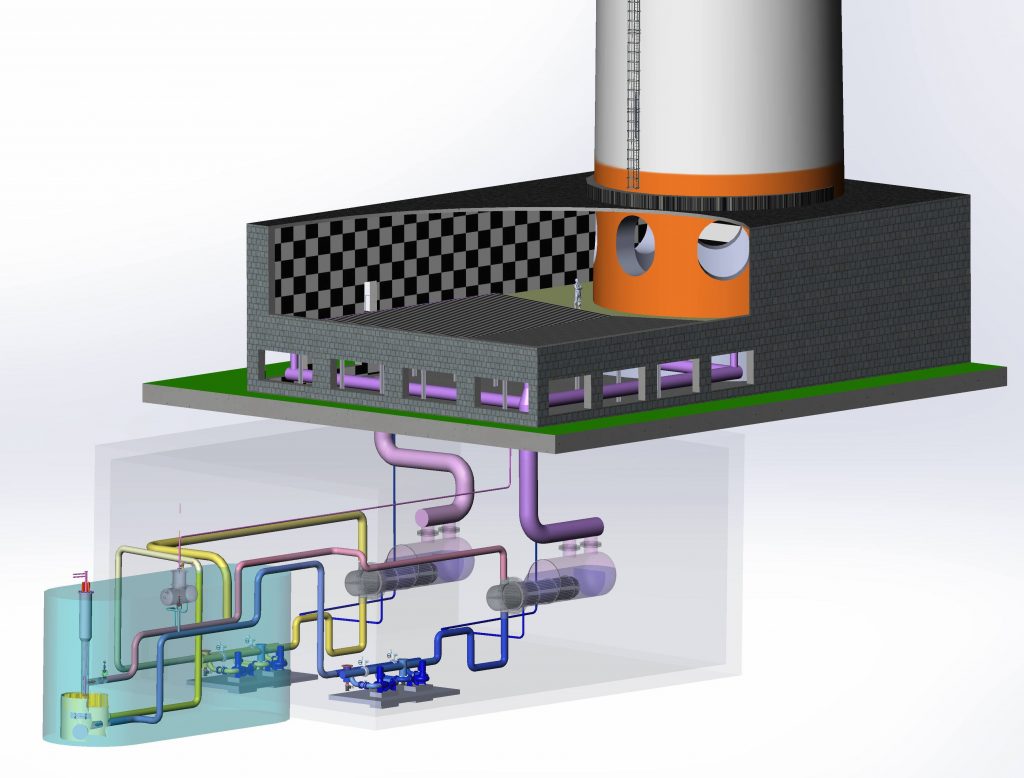

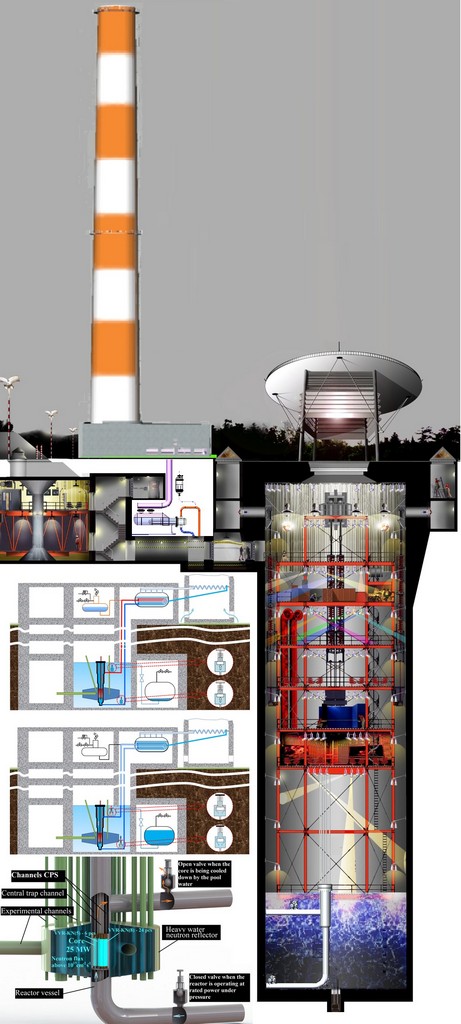

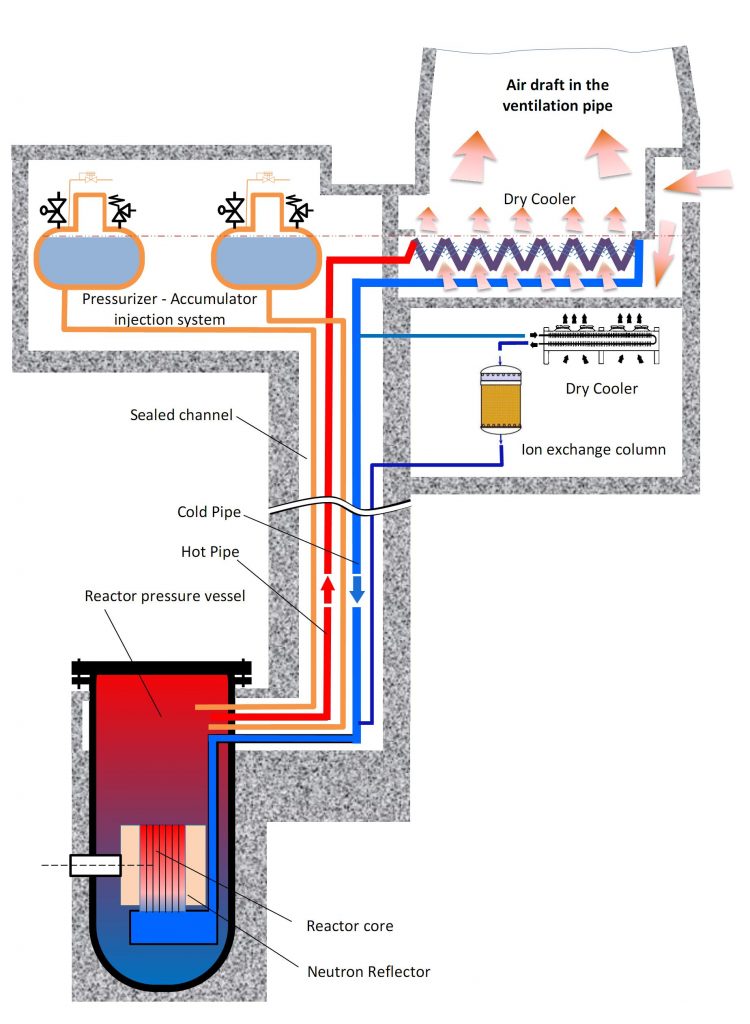

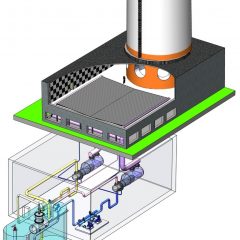

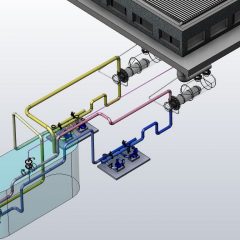

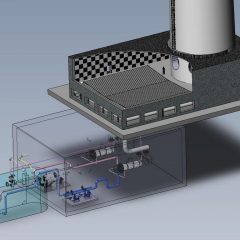

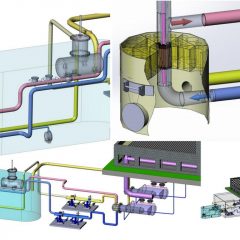

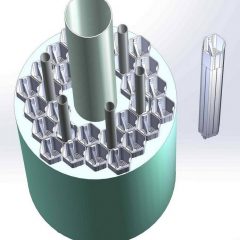

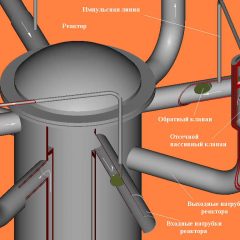

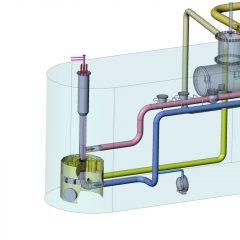

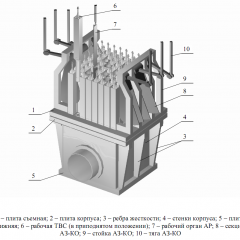

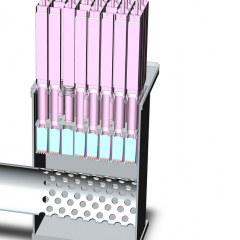

A DETAILED UNDERSTANDING OF THE DESIGN OF HEAT REMOVAL SYSTEMS FOR RESEARCH REACTORS WITH NATURAL CIRCULATION CAN BE OBTAINED FROM THREE-DIMENSIONAL MODELS MADE IN SOLID WORKS

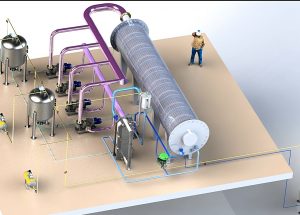

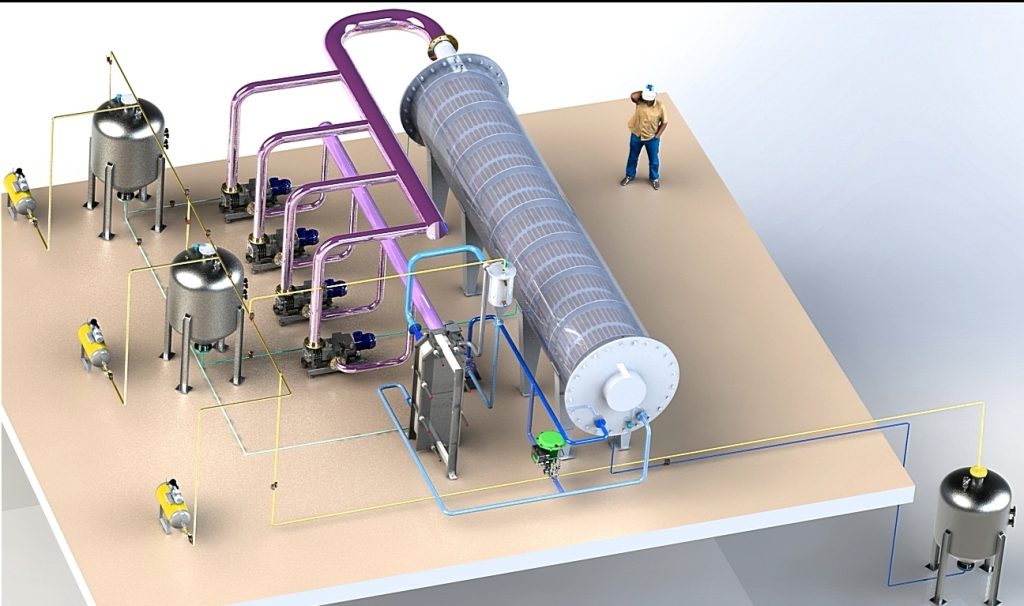

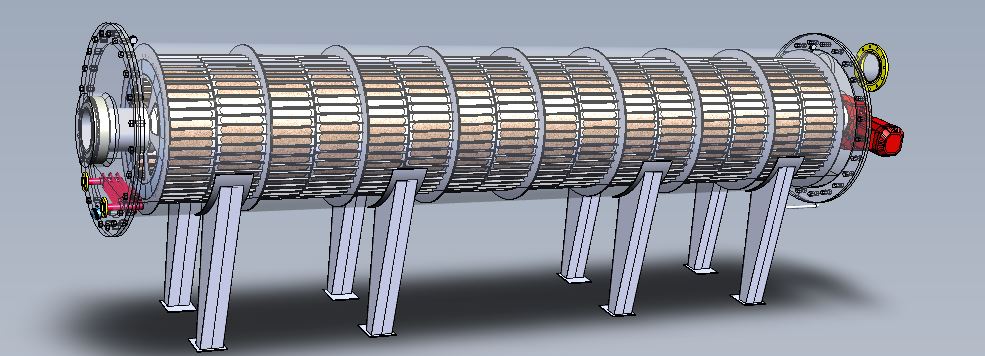

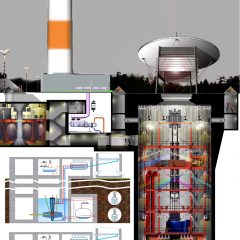

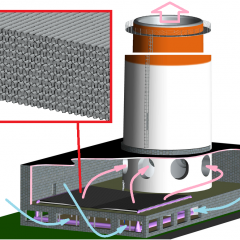

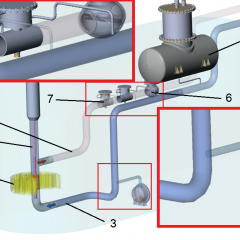

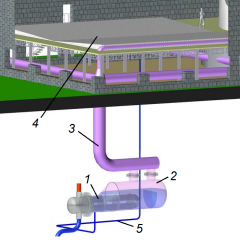

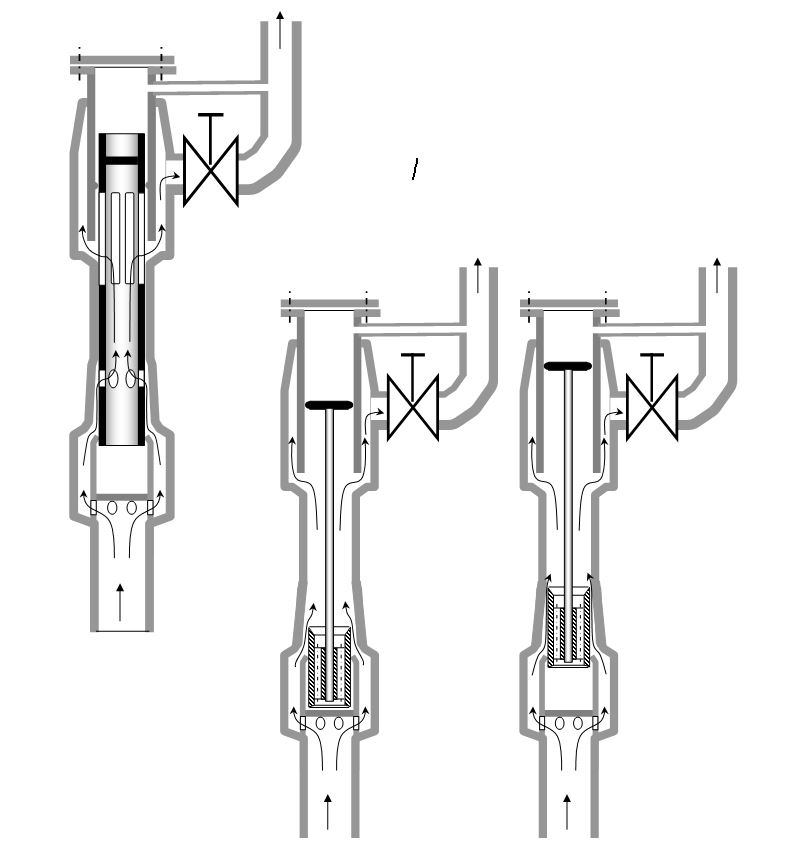

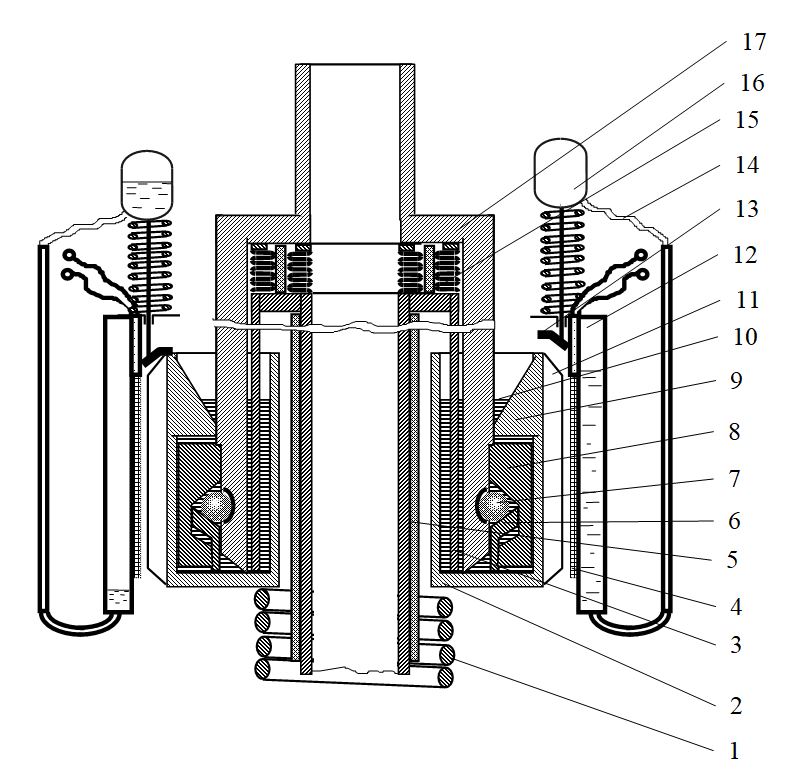

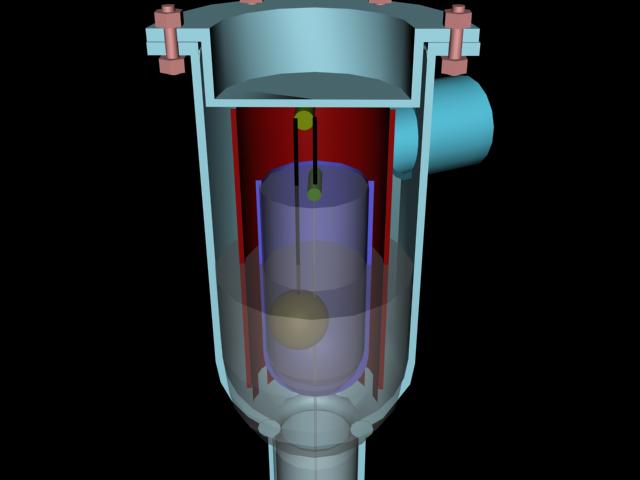

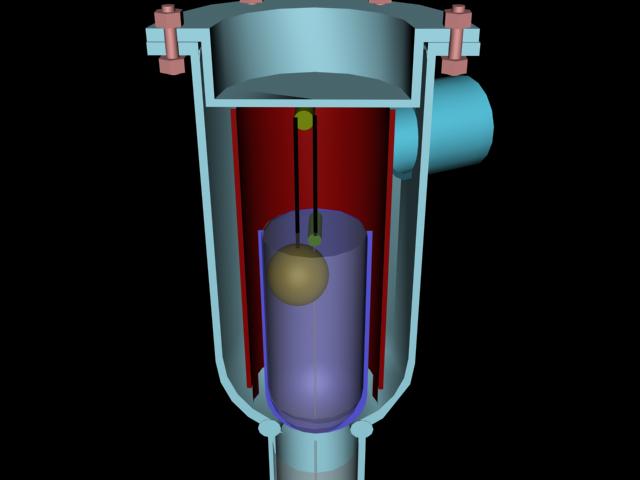

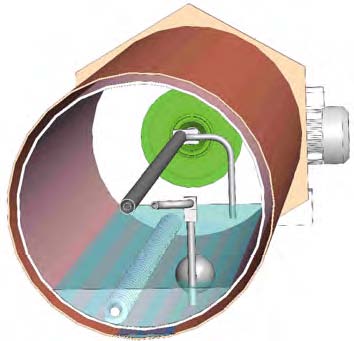

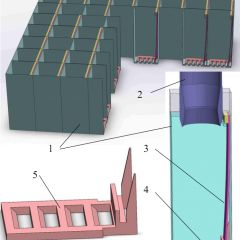

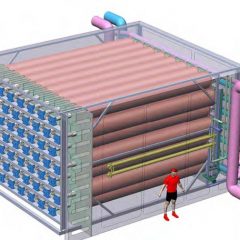

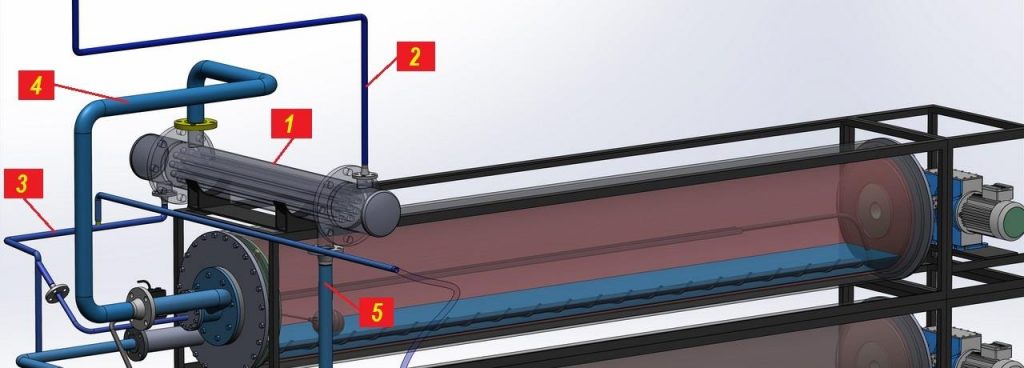

Grabcad.com provides 3D models of natural circulation research reactor heat removal systems and descriptions of their operation. The heat removal systems of the pool research reactor with a power of up to 3 MW and the reactor with a power of 25 MW use only natural convection, while the reactor plant with a power of 50 MW uses forced circulation in the primary circuit, and natural convection in the second and third circuits.

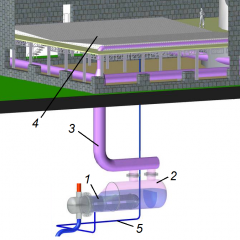

3D model of a vessel reactor up to 50 MW:

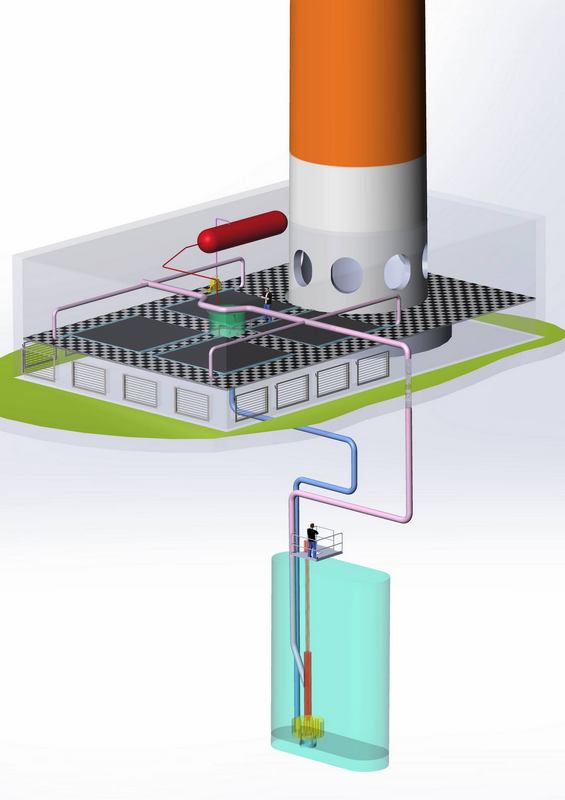

3D model of a vessel reactor up to 25 MW:

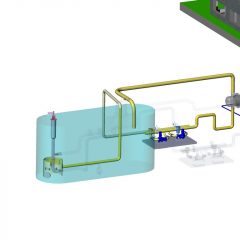

3D model of a pool reactor up to 3 MW:

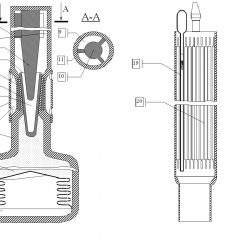

Pressurized research reactor with natural coolant circulation (10 MW)

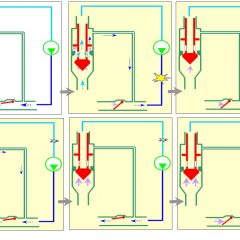

In the nuclear power industry, special attention is paid to improving the safety level of existing and planned nuclear power plants. A significant role in improving the safety level of nuclear power plants belongs to passive elements and safety systems that are put into operation without the participation of the operator, without power supply at the time of operation, without signals from safety control systems. Estimated estimates show that the use of passive safety systems increases the safety level of nuclear installations by an order of magnitude.

Passive safety systems are distinguished by:

• according to regime parameters (pressure, flow rate, level, etc.);

• according to the principle of generating an alarm signal (heating, change in pressure drop, deflection, etc.);

• according to the principle of operation (increase in hydraulic resistance, change in the balance of forces, movement, etc.);

• according to acting forces (gravity, spring pressure, etc.).

The use of safety systems with passive elements allows:

• Supplement the active safety systems of nuclear power plants with passive systems based on a different operating principle;

• reduce the impact of the operator’s actions and his possible errors;

• improve the reliability and safety of nuclear reactors.

The main safety systems used in existing nuclear power plants and considered for the designed nuclear power plants perform the functions of influencing reactivity, coolant flow and accident localization. Among them are:

• active-passive hydrodynamic shutdown systems (emergency protection) of reactors with introduction of solid absorbers into the core;

• passive and active liquid shutdown systems with introduction of liquid absorbers into the core;

• passive systems for safe cooling of the reactor core;

• pneumohydraulic passive feedback devices;

• passive valve products impact on the coolant flow.

One of these security systems is described and discussed in detail.

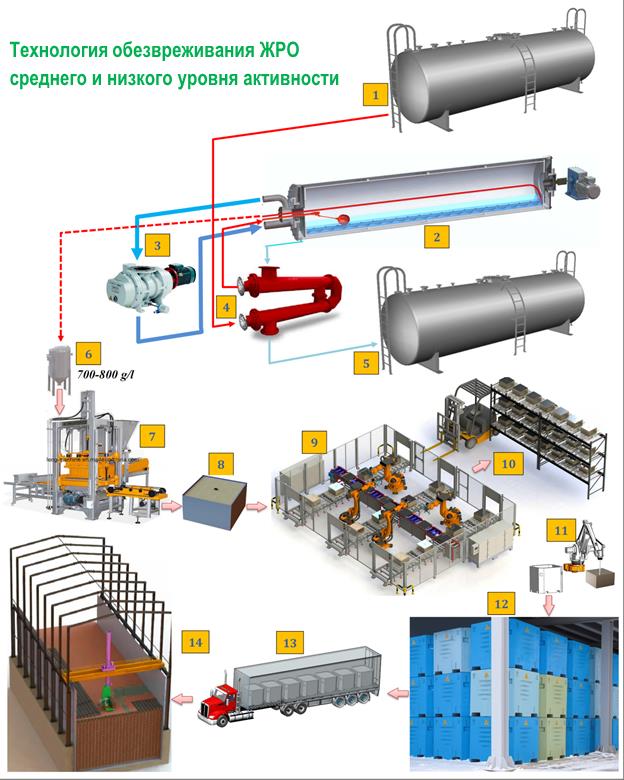

The problem of radioactive waste is of great interest to people both involved in nuclear energy and non-participants. The latter may even have more than the former, since radiophobia against the backdrop of global disasters in Chernobyl and Fukushima is a completely understandable and justified feeling. Unfortunately, the operation of nuclear fission reactors on uranium is inevitably accompanied by the production and accumulation of radionuclides that are very dangerous for humans. And although some of the radionuclides produced can bring tangible benefits to people in medicine, science and technology, the vast majority of these radionuclides, which are called radioactive waste (RW), should never be encountered by a person.

And at first glance, the isolation of radioactive waste from the environment in which a person lives is not such a difficult task. Therefore, some people think that they just need to remove these radioactive waste as far as possible — deep underground, under the ocean floor, into permafrost or even into space, and then the issue of hazardous waste will be resolved.

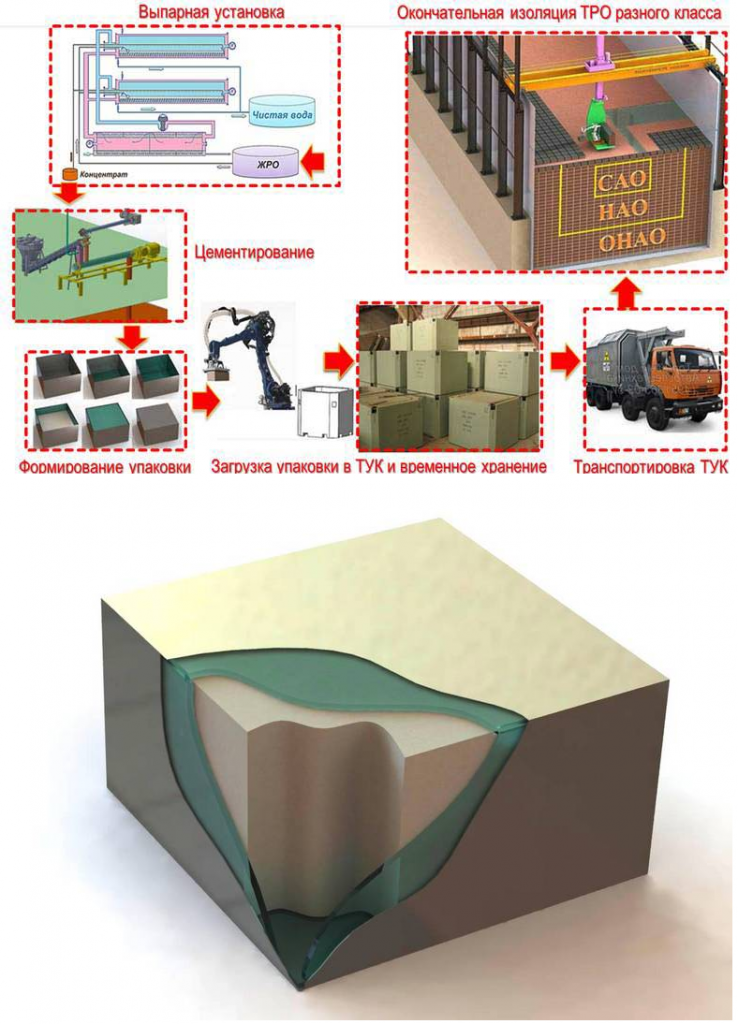

If we do not consider exotic and fantastic proposals for getting rid of radioactive waste, for example, disposal into permafrost, glaciers, volcanoes or space, then there are not so many realistic options for long-term isolation of radioactive waste. The discussion of these options is based mainly on how deep underground and into what geological formations it is better to isolate radioactive waste of one or another hazard class. But before that, hazardous radioactive substances must be bound in a solid matrix that can retain its properties for many centuries and millennia, and only then the matrix itself must be reliably isolated from the environment for the longest possible time.

Disposal concepts for low and medium level LILW waste in developed countries such as Belgium, France, Switzerland, Canada, Germany and the USA rely on low permeability host rock as a major barrier to radionuclide migration. For example, the Canadian concept relies on a multiple geologic barrier created by low permeability limestone wall rocks and overlying low permeability shales. The role that any engineered barrier system (EBS) can play in limiting the release and migration of radionuclides after the closure of a repository is generally considered to be of secondary importance. But when such concepts are considered for geological environments where potentially significant groundwater flow is possible, the role of the EBS in the operation of the repository after closure increases. The impact of groundwater flow on the reliability of the EBS and migration of radionuclides after the closure of the repository requires a careful assessment of the reliability, which may lead to the need to strengthen them to meet the requirements for the performance of the repository after closure.

Due to the complexity and high costs of implementation, most of the concepts associated with the use of geological structures, adopted in Western countries, are still under development or even no longer developed in accordance with the original designs.

In accordance with the principle of ALARA (abbr. As Low As Reasonably Achievable) adopted in the nuclear industry, formulated as the principle of optimizing doses back in 1954 by the International Commission on Radiological Protection in order to minimize the harmful effects of ionizing radiation, in the current economic conditions in practical activities for neutralization RW to reduce costs, more attention should be paid to the engineering system of barriers, primarily at near-surface disposal sites, as the least expensive.

Waste must be passively safe — liquids and sludges are converted into a solid form. It is also necessary to immobilize particulate matter and fragmented solid waste into matrices. Binder materials, bitumen, organic polymers, products of high-temperature combustion and melting, phosphate ceramics, inorganic polymers with a composition close to synthetic zeolites, glasses, glass-ceramics and natural crystalline mineral phases are considered as immobilization matrices. But in practice, waste immobilization is usually performed using cement slurries, as they have proven to be versatile, reliable, and convenient, although other immobilization matrices, such as glass or polymers, may be better suited for some waste forms. Liquid or sludge waste is cemented for disposal into a relatively homogeneous form, a cement compound, which can be placed in self-protective packages to simplify the waste management procedure in storage. However, this protection leads to an increase in the size and weight of the package, an increase in storage capacity and a significant increase in disposal costs.

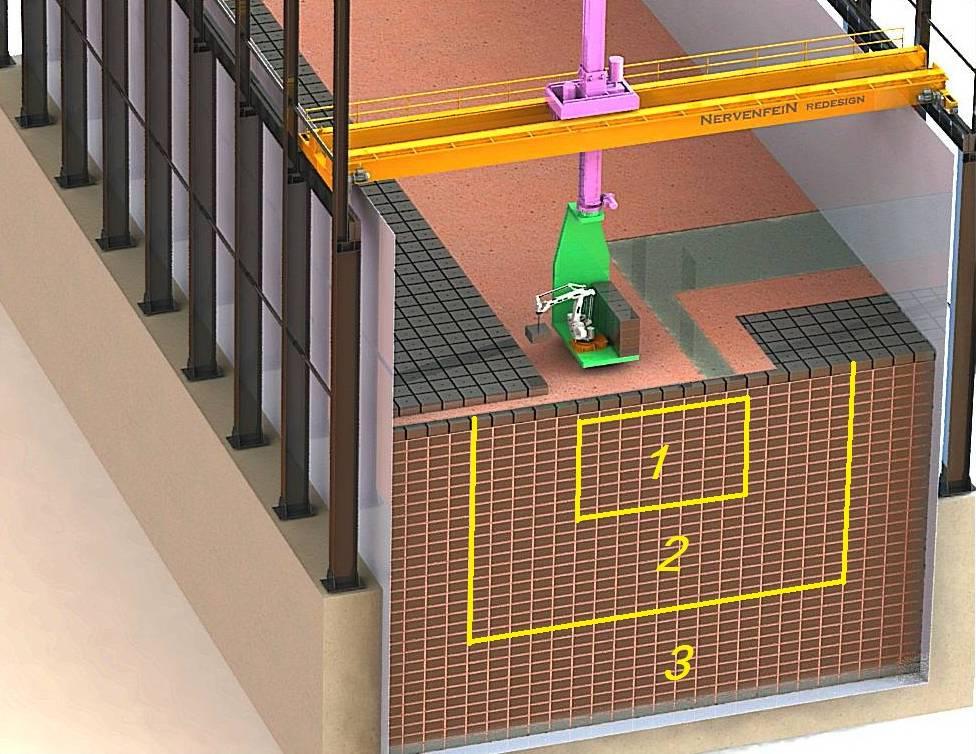

As an optimal option, one can consider an option that includes the integration of reusable shielding (transport packaging kits) and self-protection in order to minimize the amount of shielding material to be disposed of. Reusable shielding should be used only for loading and unloading and transport operations outside the storage facility, and unshielded packages should be placed in the storage facility using remote handling technology (without direct human participation), which removes restrictions on the dose rate limit at a short distance from the package.

To do this, it is necessary to develop standard (unified) packages for ILW and LLW waste in order to simplify the procedures for quality control, transportation and handling of filled packages, as well as to optimize operations, taking into account the geometric identity of the packages.

When deciding on the optimal dimensions of unshielded packages, the following considerations should be taken into account:

— packages should have a low cost;

— packaging production technology should be simple and affordable for manufacturing on conventional equipment;

— the shell of the packages must be metal, ensure complete tightness and be easy to surface decontamination;

— the filling volume of the packages should ensure that there are no problems with heating during the hydration of the cement mixture;

— after final isolation, each package must provide a reliable barrier that prevents the migration of radionuclides to the outside for centuries and millennia;

— the weight and geometrical parameters of the package must ensure the carrying out of transport and technological operations using the technology of remote circulation, i.e. without direct presence of a person near the package;— stowage of packages in the final isolation point should ensure the maximum density of solidified RW per unit of useful storage volume;

— the structure of the engineering system of barriers that prevent the migration of hazardous radionuclides into the environment must be multi-layered and built on the basis of materials that retain their insulating, filtering and sorbing properties for many millennia;

— typical packages should be suitable for final isolation in one disposal facility of solidified RW of different radiation hazard classes.

Nuclear power cannot be imagined without isotope separation. By this, as a rule, is meant the division by nature of a mixture of isotopes into components containing individual (target) isotopes. Most often, the separation of a mixture of isotopes is reduced to the separation of the target isotope from the mixture or simply to its concentration. An example is the extraction of 6Li, 235U, D. Unfortunately, the separation of isotopes is always associated with significant difficulties, since isotopes, which are variations of one chemical element, differ slightly in mass, chemically behave almost the same, only in the speed of some reactions there is a difference .

Isotope separation methods are based on differences in the properties of isotopes and their compounds associated with differences in the masses of their atoms (isotope effects). Since the relative mass difference of isotopes is very small for most elements, the isotope effects are also negligible. This determines the complexity of the problem. In any separation unit, the initial mixture is divided into at least two fractions, one of which is enriched in the enriched isotope at the expense of the others. There are molecular-kinetic, physico-chemical and electromagnetic methods of isotope separation.

The first two methods are based on the difference in the average properties of isotopic compounds due to the difference in isotope masses. For these methods, the separation factor α is usually small, and the throughput G can be large. Electromagnetic methods are based on the different behavior of isotopes in electric and magnetic fields. As a rule, these methods make it possible to obtain high values of the separation factor α at a low productivity G in one cycle of isotope separation. For most methods, α is only slightly greater than unity, so a single isotope separation operation must be repeated many times to obtain a high isotope concentration. Only with electromagnetic separation α is 10–1000 for 1 separation cycle. The choice of isotope separation method depends on the properties of the substance to be separated, the required degree of separation, the required number of isotopes, the efficiency of the process (with a significant scale of isotope production), etc.

The operation of nuclear reactors is impossible without the production of U-235 and/or D (H-2) isotopes. You can start a chain reaction of fission of uranium nuclei either by using heavy water (D2O) with deuterium atoms as a coolant and moderator — and then the chain reaction will go on even with the natural isotope composition of uranium, or use uranium enriched with the U-235 isotope — and then as a coolant and moderator, you can use plain water. Obviously, in both cases, isotope separation technology is indispensable.

The topic of discussion will be the optimization of the technology for separating water molecules by hydrogen isotopes, which can be applied in various industries: production of heavy (D2O) water for the nuclear industry; purification of radioactive water from tritium during the liquidation of the consequences of the accident at the Fukushima nuclear power plant or heavy water coolant at nuclear reactors; reduction of the natural concentration of heavy hydrogen isotopes in water for biological and medical purposes, etc.

Millions of people are experiencing a shortage of fresh water, fresh water supplies are rapidly declining, and the demand for it is growing. The lack of fresh water in some regions of the Earth is becoming a serious problem that poses a threat to the development of mankind and the preservation of the environment.

The lack of water and energy are the two main global problems facing modern society. Right now, almost a fifth of the world’s population lives in areas with water scarcity, and another 1.6 billion people live in areas with economic water scarcity due to technical or financial restrictions on getting fresh water, even when water is available. Therefore, solar water treatment methods are considered attractive for obtaining clean water from a variety of non-drinkable water sources, including sea water, river/lake water, and polluted water in an environmentally safe and sustainable manner.

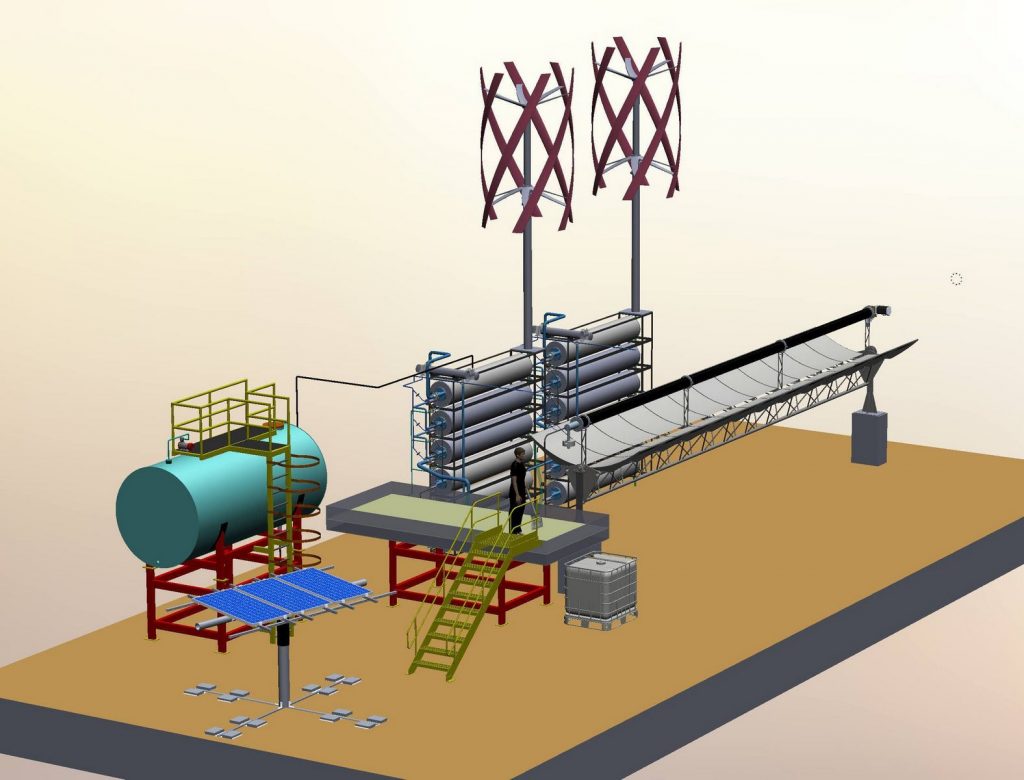

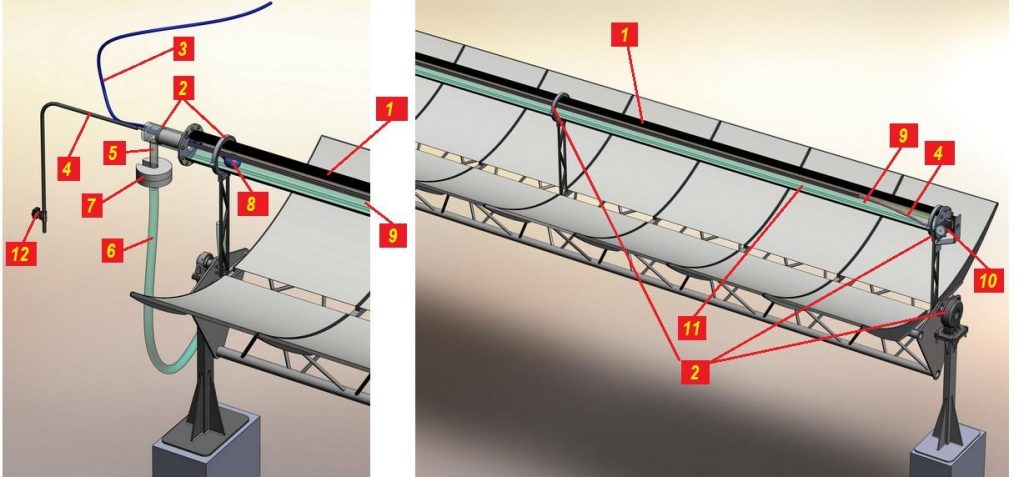

In particular, solar desalination in countries with hot arid climates can use widely available and free solar energy to produce drinking water from natural water sources, making this technology promising for addressing water scarcity.

In addition, an important new application of solar evaporation has recently emerged — zero liquid discharge (ZLD) wastewater desalination using solar energy. Compared to traditional technologies, ZLD solar desalination produces solid salt as the only by-product and uses sunlight as the only source of energy, making it less energy intensive and more cost-effective and affordable.

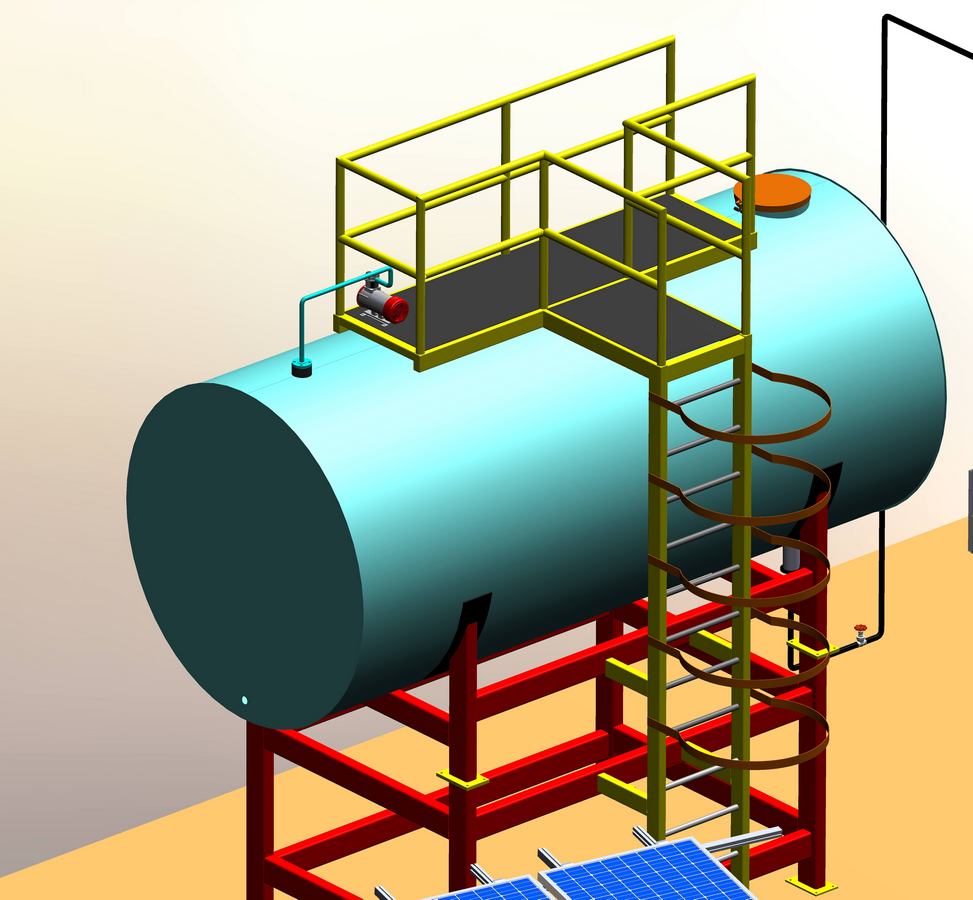

Next, the concept of a small autonomous solar multi-stage desalination plant based on film evaporation drums with zero liquid (brine) discharge and a desalinated water capacity of up to 5000 liters per day is considered.

When choosing equipment for designed installations, it is usually oriented towards already known and commercially available devices. However, often their design does not meet the requirements of the project, and then it is necessary to develop special equipment in accordance with the purpose of the installation. And even when, for example, a conventional heat exchanger is required, the stringent design requirement for the absence of scale formation on the heat exchanger tubes of the plant when working with scale-forming solutions can lead to the abandonment of the use of conventional recuperative heat exchangers and require the development of a special heat exchanger with on-line descaling.

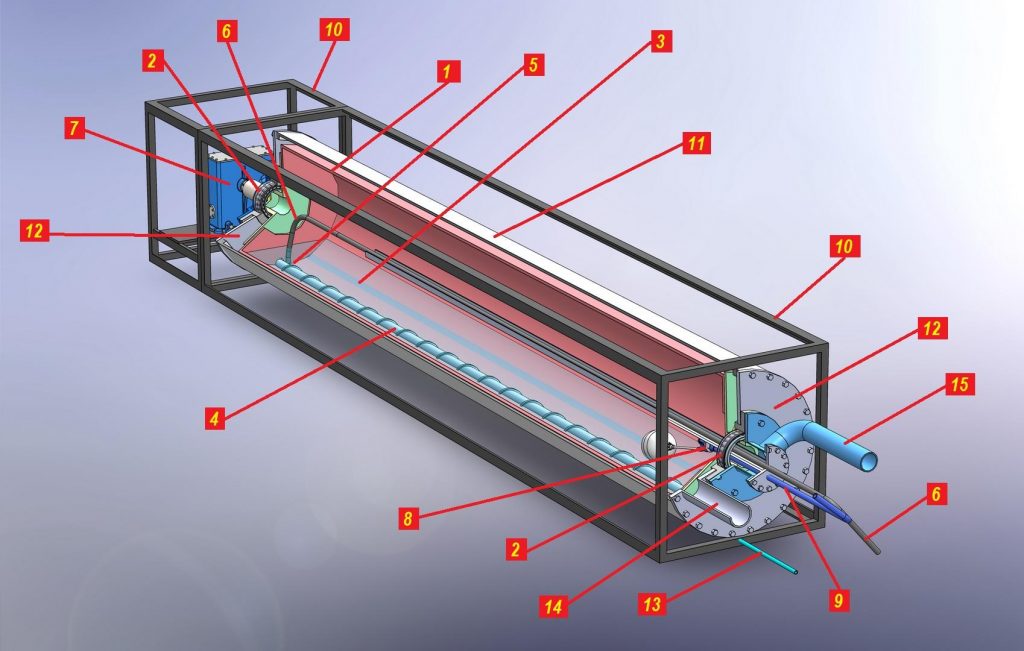

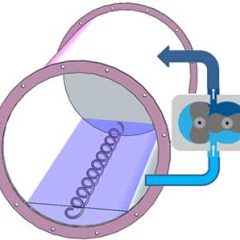

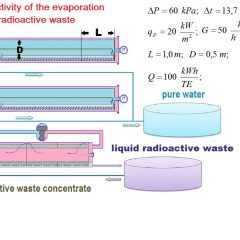

Invention relates to processes and devices for chemical engineering and can be used in power, oil and gas, nuclear, chemical, food, pharmacological and other industries for rectification, absorption, vacuum evaporation, desorption, concentration, etc. processes in the gas-liquid system, as well as in absorption systems aimed at preventing the release of hydrocarbon vapors into the atmosphere at oil refineries, for purifying steam from radioactive aerosols during the concentration of liquid radioactive waste by evaporation, etc.

invention allows simplifying the design of the apparatus, providing a higher manufacturability, achieving a higher efficiency of heat and mass transfer processes, increasing the productivity of the apparatus, using the kinetic energy of the gas or steam entering the apparatus as a driving force to drive the rotation of the packing structures.

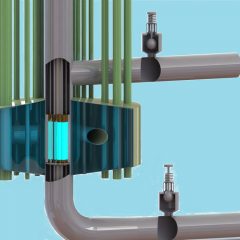

To conduct experiments on a research reactor in which the parameters of destruction and melting of nuclear fuel (fuel elements) are studied, loop channels are used, the connection of which with the cooling circuit is a big problem due to high dose loads. For remote connection and disconnection of loop channels with the cooling circuit, a detachable connection design is proposed, which allows this procedure to be carried out remotely.

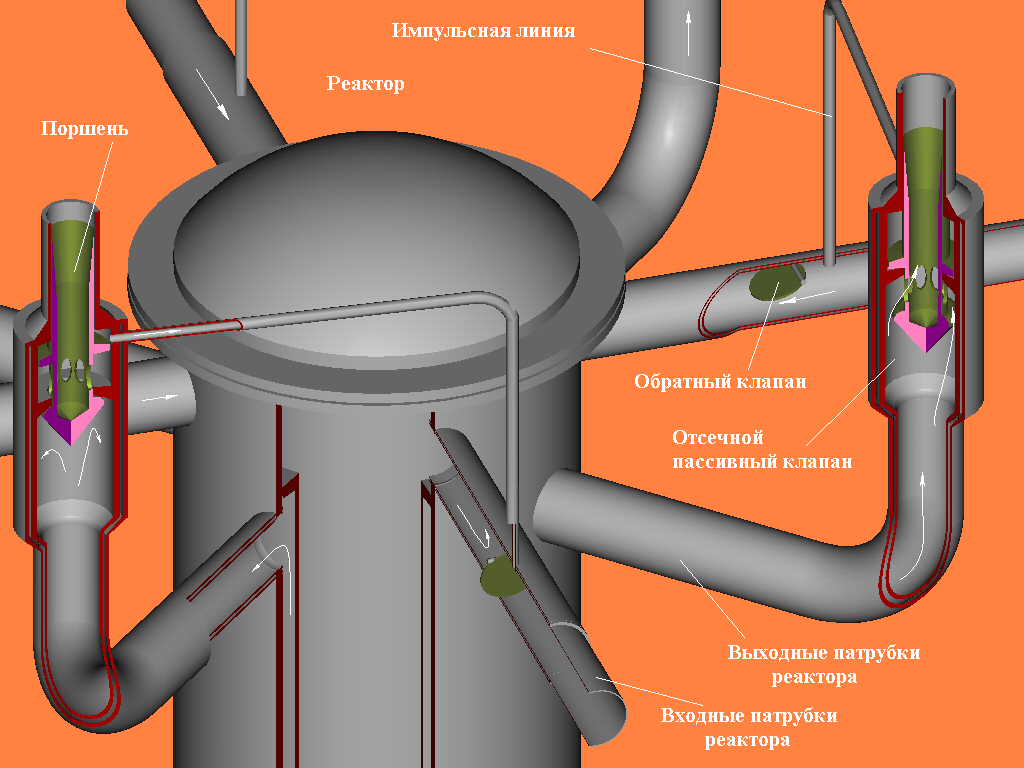

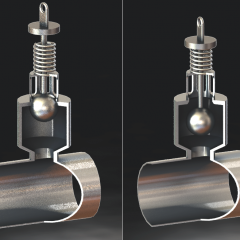

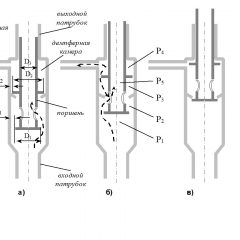

One of the determining factors in the destruction of fuel elements in pressurized water reactors is the crisis of heat transfer during boiling, leading to a sharp increase in the temperature of the fuel cladding, its melting and the release of the fuel composition into the coolant. The previously considered direct-acting emergency protection devices did not take into account this mechanism, and therefore, practically lost their effectiveness due to their inertia. Following the logic of “knocking out a wedge with a wedge”, the most rational physical effect, on the basis of which the work of direct-acting emergency protection should be built, is the same heat transfer crisis, which has a pronounced threshold. This solves the main problem that did not allow earlier to consider passive emergency protection devices as equivalent to currently operating active systems, namely, it provides a speed that exceeds the speed of any suppressed (by this tool) emergency processes and / or their combinations leading to exceeding the established safety limits.

Patents

Выдан 28 июн. 2021 г.

Узиков Виталий Алексеевич, Узикова Ирина Витальевна, Рогожкин Сергей Владимирович

Выдан 10 сент. 2006 г.RU RU56706U1

Ярослав Кимович Кочнов, Олег Борисович Жарков, Константин Владимирович Родионов, Денис Георгиевич Тарло, Юрий Евгеньевич Штында, Виталий Алексеевич Узиков

Выдан 10 дек. 1998 г.RU RU96117616A

В.А. Узиков, Р.И. Коротков

Выдан 10 дек. 1998 г.RU RU96117616A

В.А. Узиков

Выдан 20 июл. 1996 г.RU RU 2064098 C1

Виталий Алексеевич Узиков

Виталий Алексеевич Узиков

Виталий Алексеевич Узиков, Ирина Витальевна Узикова, Ильдар Радикович Сулейманов

researchgate · 12 авг. 2021 г.

Выдан 27 июл. 2013 г.RU RU2488421C1

Виталий Алексеевич, УзиковЯрослав Кимович, Кочнов, Наталья Евгеньевна Осипова, Ирина Витальевна Узикова

Выдан 10 сент. 2006 г.RU RU 56 705 U1

Ярослав Кимович Кочнов, Олег Борисович Жарков, Константин Владимирович Родионов, Денис Георгиевич Тарло, Юрий Евгеньевич Штында, Виталий Алексеевич Узиков

Выдан 3 апр. 2006 г.RU RU 2309472 C1 .

Ярослав Кимович Кочнов, Олег Борисович Жарков, Константин Владимирович Родионов, Денис Георгиевич Тарло, Юрий Евгеньевич Штында, Виталий Алексеевич Узиков

Выдан 27 авг. 1999 г.RU RU2136061C1 .

Виталий Алексеевич Узиков

Выдан 27 авг. 1999 г.RU RU2136061C1 .

Виталий Алексеевич Узиков

Виталий Алексеевич Узиков

Виталий Алексеевич Узиков

Publications

Scientific work is when you read two books that no one has ever read in order to write a third book that no one will read.

researchgate · 19 авг. 2021 г

Vitaly Uzikov (2021).

researchgate · 16 авг. 2021 г.

Vitaly Uzikov, Irina Uzikova (2021)

researchgate · 3 июн. 2021 г.

Vitaly Uzikov (2021).

researchgat · June 2021

Vitaly Uzikov, Irina Uzikova (2021)

researchgat · June 2021

Vitaly Uzikov (2021)

Vitaly Uzikov (2021)

Vitaly Uzikov (2021)

ТОПОРОВ ЮРИЙ ГЕННАДЬЕВИЧ, ТАРАСОВ ВАЛЕРИЙ АНАТОЛЬЕВИЧ, РОМАНОВ ЕВГЕНИЙ ГЕННАДЬЕВИЧ, КУПРИЯНОВ АЛЕКСЕЙ ВЛАДИМИРОВИЧ, АНДРЕЕВ ОЛЕГ ИВАНОВИЧ, ШИМБАРЕВ ЕВГЕНИЙ ВАСИЛЬЕВИЧ, ГОРДЕЕВ ЯН НИКОЛАЕВИЧ, ПЕТЕЛИН АЛЕКСЕЙ ЛЕОНИДОВИЧ, САЗОНТОВ СЕРГЕЙ АРКАДЬЕВИЧ, УЗИКОВ ВИТАЛИЙ АЛЕКСЕЕВИЧ

ТАРАСОВ В.А., РОМАНОВ Е.Г., КУПРИЯНОВ А.В., УЗИКОВ В.А., АКИМОВ Л.В., МАРИХИН Н.Ю., МАЛКОВ А.П., ПИМЕНОВ В.В., ПЕТЕЛИН А.Л., САЗОНТОВ С.А.

АНДРЕЕВ О.И., БУТКАЛЮК П.С., АБДУЛЛОВ Р.Г., ТАРАСОВ В.А., КУПРИЯНОВ А.В., УЗИКОВ В.А.

КУПРИЯНОВ АЛЕКСЕЙ ВЛАДИМИРОВИЧ, МАЛКОВ АНДРЕЙ ПАВЛОВИЧ, РОМАНОВ ЕВГЕНИЙ ГЕННАДЬЕВИЧ, ТАРАСОВ ВАЛЕРИЙ АНАТОЛЬЕВИЧ, ПЕТЕЛИН АЛЕКСЕЙ ЛЕОНИДОВИЧ, САЗОНТОВ СЕРГЕЙ АРКАДЬЕВИЧ, УЗИКОВ ВИТАЛИЙ АЛЕКСЕЕВИЧ

Т.А. Осипова. В.А. Старков. В.А. Узиков

КУЗИН М.А., БОРОВКОВ А.А., БОЧКАРЁВА Н.И., УЗИКОВ В.А., МАКАРОВ А.О., КОЗНОВ Г.И., ФУНТОВ А.А.

G. D. Gataullina V.F,. Uzikov, T. A. Osipova

БУТКАЛЮК П.С., КУПРИЯНОВ А.В., КУЗНЕЦОВ Р.А., РОМАНОВ Е.Г., ТАРАСОВ В.А.1, УЗИКОВ В.А.

Т.А. Осипова, М.Ф. Валишин, В.А. Узиков, П.С. Палачёв

ОСИПОВА ТАТЬЯНА АНДРЕЕВНА, УЗИКОВ В.А., ПАЛАЧЁВ П.С., МАКИН Р.С.

РЫБИН АНАТОЛИЙ АЛЕКСЕЕВИЧ, УЗИКОВ ВИТАЛИЙ АЛЕКСЕЕВИЧ, СЕРЕБРЯКОВ ВЛАДИМИР ВАЛЕРИАНОВИЧ, НИКОЛАЕВА ЕКАТЕРИНА АНДРЕЕВНА

GATAULLINA G.D., UZIKOV V.A., OSIPOVA T.A.

T.A. Osipova, M.F. Valishin, V.A. Uzikov, P.S. Palachev

КРАСНОВ Ю.А., МАЛКОВ А.П., МАРИХИН Н.Ю., ПЕТЕЛИН А.Л., ПИМЕНОВ В.В., УЗИКОВ В.А., ЧЕКАЛКИН С.И.

researchgate · 12 авг. 2021 г.

Science and Technology of Nuclear Installations / 2022 / Article

Vitaly Uzikov, Ildar Suleimanov, and Irina Uzikova (2022).

researchgate · 12 авг. 2021 г.

Vitaly Uzikov (2021).

Nuclear Technology and Radiation Protection 2019 Volume 34, Issue 2, Pages: 107-121 • 13 нояб. 2019 г

Vitaly Uzikov, Irina Uzikova (2021)

researchgate · 1 авг. 2021 г.

Vitaly Uzikov (2021).

researchgate · 5 мая 2021 г.

Vitaly Uzikov (2021).

researchgate · 15 апр. 2021 г.

Vitaly Uzikov (2021).

researchgate · 14 апр. 2021 г.

Vitaly Uzikov (2021).

Scientific annual report of JSC "SSC RIAR" · 11 апр. 2021 г.

ЗВИР А.И., ИЖУТОВ А.Л., ТАРАСОВ В.А., РОМАНОВ Е.Г., КУПРИЯНОВ А.В., ПЕТЕЛИН А.Л., САЗОНТОВ С.А., МАЛКОВ А.П., ПИМЕНОВ В.В., УЗИКОВ В.А., АКИМОВ Л.В., ТАБАКИН Е.М., ТОРГАШОВ И.В., КИЗИН В.Д., ЮСУПОВ А.Н., ОРЛОВ Г.

Scientific annual report of JSC "SSC RIAR" · 11 апр. 2021 г.

Т А. ОСИПОВА, В.А. УЗИКОВ, Р.С. МАКИН

Scientific annual report of JSC "SSC RIAR" • 6 апр. 2021 г.

Т А. ОСИПОВА, В.А. УЗИКОВ, Р.С. МАКИН

Scientific annual report of JSC "SSC RIAR" • 6 апр. 2019 г.

ТАРАСОВ В.А., РОМАНОВ Е.Г., КУПРИЯНОВ А.В., УЗИКОВ В.А., ЮСУПОВ А.Н., КИЗИН В.Д., МИХАЙЛОВ П.А.

Energy and Technology 4(1):1-6 • 11 сент. 2018 г.

Tatiana Osipova, Vladimir Starkov, Vitaky Uzikov

Scientific annual report of JSC "SSC RIAR" • 13 апр. 2018 г.

ЗВИР А.И., ТАРАСОВ В.А., РОМАНОВ Е.Г., РЯБОВ Д.В., СИВУХА В.И.1, САЗОНТОВ С.А., КИЗИН Д.В1, МИХАЙЛОВ П.А., УЗИКОВ В.А., СЕМЁНОВА Е.А.

Scientific annual report of JSC "SSC RIAR" • 18 мая 2017 г.

ИЖУТОВ А.Л., ИВАНОВ В.В., САЗОНТОВ С.А., СТАРКОВ В.А., ПИМЕНОВ В.В., ОСИПОВА Т.А., УЗИКОВ В.А.

Scientific annual report of JSC "SSC RIAR", 2017. Вып. 1. С. 57–62. • 6 апр. 2017

М.А. Кузин, А.А. Боровков, Н.И. Бочкарёва, В.А. Узиков,А.О. Макаров, Г.И. Кознов, А.А. Фунтов

Scientific annual report of JSC "SSC RIAR" • 15 авг. 2016 г.

УЗИКОВ В.А., ОСИПОВА Т.А.

Scientific annual report of JSC "SSC RIAR" • 11 апр. 2016 г.

БУТКАЛЮК И.Л., БУТКАЛЮК П.С., БЕЛОБРОВ И.С., КУЗНЕЦОВ Р.А., РОМАНОВ Е.Г., УЗИКОВ В.А.

QUESTIONS OF ATOMIC SCIENCE AND TECHNOLOGY. SERIES: MATERIALS SCIENCE AND NEW MATERIALS • 14 нояб. 2015 г.

Vitaly Uzikov

ИЗВЕСТИЯ ВЫСШИХ УЧЕБНЫХ ЗАВЕДЕНИЙ. ЯДЕРНАЯ ЭНЕРГЕТИКА (Обнинск) • 13 мая 2015 г.

ОСИПОВА Т.А., ВАЛИШИН М.Ф., УЗИКОВ В.А., ПАЛАЧЕВ П.С.

ИЗВЕСТИЯ САМАРСКОГО НАУЧНОГО ЦЕНТРА РОССИЙСКОЙ АКАДЕМИИ НАУК • 6 апр. 2014 г.

ОСИПОВА ТАТЬЯНА АНДРЕЕВНА, УЗИКОВ ВИТАЛИЙ АЛЕКСЕЕВИЧ, МАКИН РУСЛАН СЕРГЕЕВИЧ

ИЗВЕСТИЯ САМАРСКОГО НАУЧНОГО ЦЕНТРА РОССИЙСКОЙ АКАДЕМИИ НАУК • 5 апр. 2013 г.

ГАТАУЛЛИНА ГУЗЯЛЬЯ ДЯВДАТОВНА, ОСИПОВА ТАТЬЯНА АНДРЕЕВНА, УЗИКОВ ВИТАЛИЙ АЛЕКСЕЕВИЧ

Альтернативная энергетика и экология. - 2010. - N 2 (82) • 8 авг. 2010

И.В. Узикова , В А. Узиков , И.Г. Меринов

uzikof@gmail.com

uzikov62@mail.ru

Address

Bratskaya st., 27 apt. 61 Dimitrovgrad, Ulyanovsk region, Russia, 433515

Call Us

+7 917 622 40 47

Аccumulated experience

An integral part of the accumulated experience is the analysis of one's own mistakes

Ideas

A fresh look at the problem from the outside, not constrained by knowledge of already known solutions, can lead to a productive idea of a non-trivial solutiont.

Implementation

The ability to conduct a numerical analysis of an idea that has arisen can be the first step towards its implementation.