Safety enhancement concept for research reactors a mine structure

During the years of the Cold War, vast experience has been accumulated in high-tech engineering silo structures designed for silo-based strategic intercontinental ballistic missiles. On the other hand, after severe nuclear accidents, the safety issues of newly constructed nuclear reactor facilities for research and production of isotopes have acquired particular importance. The combination of the accumulated experience in the creation and operation of missile silos with new concepts for ensuring the safety of research reactor facilities will significantly expand the possibilities of using reactor technologies to solve scientific and applied problems. At the same time, a number of acute problems are removed, both with the construction of the reactor plant and its dismantling after decommissioning. Moreover, it should be taken into account that the cost of decommissioning a reactor plant and its dismantling is significantly higher than the cost of building this plant. The proposed concept of silo-type reactor plants makes it possible to comprehensively solve the problems of safety, physical protection, and decommissioning at minimized total costs.

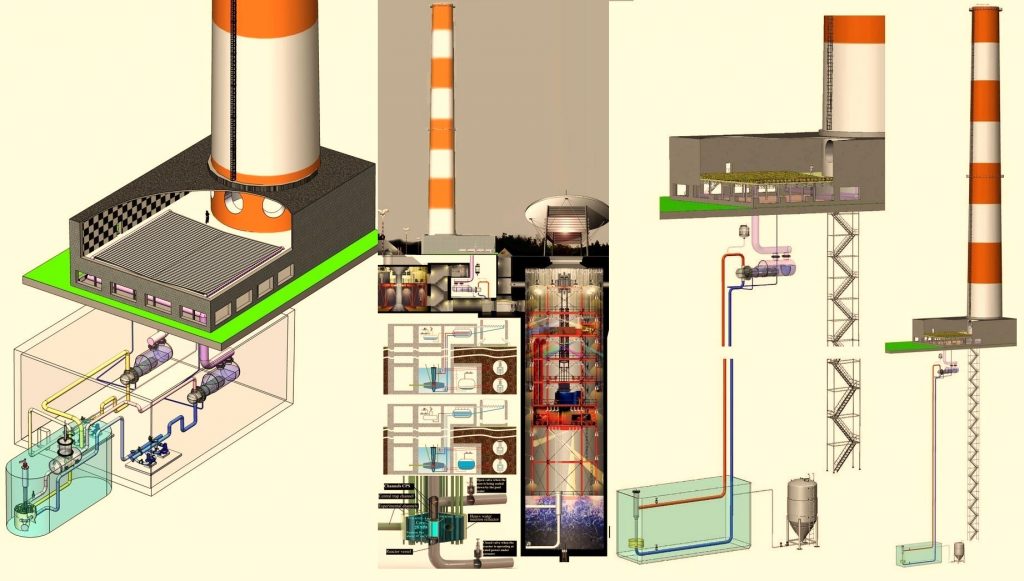

The proposed innovative concept of a research reactor facility is based on safety enhancement due to the utmost simplification of the design of systems for removing heat from the core and using only passive systems in them when organizing the circulation of the coolant in all cooling circuits.

The passivity of cooling systems is based on the natural circulation of the coolant, the driving force in which is gravity and the difference in densities in the upstream and downstream sections. The intensity of the natural circulation of the coolant, other things being equal, is proportional to the height of the circulation loop, so the design of the cooling systems of the proposed reactor facility imposes certain requirements on the altitude parameters of the primary circuit and the exhaust pipe. However, it should be noted that the intermediate circuit heat transfer mechanism, based on the heat pipe principle, does not require a large circulation circuit height to transfer a large thermal power.

To ensure that the requirements for the height of the natural circulation circuit of water in the primary circuit and air in the circuit of heat transfer to the final heat sink can be met, for example, experience in creating high-tech engineering structures — missile silos designed for strategic ICBMs, as well as experience in creating large chimneys.

The principal feature of the presented passive heat removal system is the absence of active elements in the cooling circuits (for example, circulation pumps, shut-off and control valves, etc.), failures of which or incorrect actions of personnel in their management can affect safety.

An important element of the radiation safety of such a reactor plant is the presence of an intermediate circuit with a non-radioactive coolant, made according to the principle of operation of a heat pipe (thermosyphon). This design excludes the release of radioactive coolant into the environment in case of any depressurization of the cooling circuits. The proposed design of the core cooling circuits includes only vessels, pipelines and heat exchangers that do not interfere with the natural circulation of the coolant in any mode. The absence of elements with mechanical moving parts can significantly reduce the likelihood of equipment failures and increase the reliability of the cooling system while reducing its cost.

The independence of the operation of the cooling system from the power supply and the self-regulation of the coolant flow rate depending on the power of the reactor ensures the convenience of controlling the reactor and extends the operating modes without complicating the control systems.

The simplicity of the heat sink system facilitates the analysis of safety in emergency conditions and conveys the reliability of the predicted development of initiating events.

These advantages give developers ample opportunities to search for optimal and competitive design solutions that provide a wide range of research in areas [1]:

- nuclear physics,

- solid state physics,

- radiation materials science,

- neutron activation analysis of matter,

- neutron radiography of various products,

- radiation doping of silicon,

- production of isotopes for medical industrial purposes etc.

Compliance of the proposed concept with the design principles of advanced research reactors

As a result of the development of the standard, special attention was paid to the safety and research of reactors [2], as well as the conceptual provisions and results of research on advanced and research reactors for research centers, described in [1] and described below.

Reliability

- The physical basis of the mechanism of natural circulation of water and air is simple and reliable. Modern calculation programs make it possible to estimate with sufficient accuracy the dynamic processes of the development of natural circulation in time, even in complex schemes. The use of only passive equipment in the cooling circuit without mechanical moving parts (pipelines, vessels, heat exchanger) ensures high reliability of the entire system [2].

- The stability of the circulation process during the lifting movement of the coolant in the core ensures high thermal reliability even with an accelerated output to power, leading to boiling on the surface of the fuel elements. At the same time, the circulation of the coolant in the circuit is enhanced due to a decrease in the average density of the coolant in the lifting section, increasing the coolant flow through the reactor core, which ensures a return to the normal thermal-hydraulic parameters of the reactor if the power does not exceed the limit of normal operation. It should be noted that when meeting the requirements for the reactor core to ensure natural self-protection (negativity of the effect of «emptiness» of reactivity), boiling up of the coolant in the core leads to negative reactivity and a decrease in thermal power

Security

- The high water level above the core in the reactor vessel provides radiation protection for personnel during transport and reloading operations.

- The presence of passive natural circulation valves in the reactor pool on the inlet and outlet pipelines makes it possible to maintain circulation through the core in the event of a pipeline rupture. This ensures safe cooling of fuel assemblies in any emergency with depressurization of the primary circuit.

- An important safety factor for a natural circulation reactor is that all systems that provide heat removal both in normal and emergency conditions are completely passive and do not depend on a power source.

Flexibility

The versatility of the cooling system makes it possible to implement various layouts of the reactor core for the selected size of the reactor pressure vessel. Open access to the channels of the reflector, located in the pool around the reactor vessel, ensures the convenience of irradiation and replacement of irradiation devices even during reactor operation.

Simplicity

The extreme simplicity of the circulation circuit ensures the convenience of reactor maintenance and the absence of the need for scheduled preventive maintenance of complex equipment of the reactor cooling system (pumps, shut-off and control valves, check valves) due to their absence. In [3], the advantages of the technological scheme of passive heat removal from the active zone of a research reactor using natural circulation are shown. It is very important that the simplification of the circulation loop makes it possible to carry out a qualitative and reliable analysis of emergency situations in order to justify the safety of a reactor plant, and the number of possible emergency situations is sharply reduced.

Implementation of the concept of a mine-type research reactor

The accumulated experience in creating high-tech engineering structures for silo-type ICBMs, as well as the problem of decommissioning missile silos as part of the reduction of strategic weapons, allows us to consider an unusual option for creating research reactor installations with increased safety. The location of the reactor at a considerable depth makes it possible to ensure high efficiency of the natural circulation of the coolant in the primary circuit, and also removes many safety issues (independence from power sources, physical protection, protection against external influences — explosions, aircraft crashes, etc.) . In addition, many complex issues related to ensuring radiation safety and decommissioning the reactor facility are removed.

The possibility of implementing the concept of a high-flux increased safety research reactor on the principles described above is illustrated by the description of the design of reactor installations at the links:

4. Discussion of results

- • A conceptual three-dimensional model of a reactor facility with a heat removal system based on natural circulation is presented. The advantages of creating a simple and reliable passive system for cooling the core of a research reactor, built on the principle of natural coolant convection, are substantiated;

• The presence of an intermediate circuit operating on the principle of a heat pipe (thermosyphon) eliminates the risk of radioactive coolant getting into the environment. The operation of this circuit provides high heat transfer efficiency with a simple design and the absence of mechanical moving parts, which determines the reliability of the system;

• Air cooling of the reactor plant using an exhaust pipe removes the problem of cooling tower water treatment to prevent the formation of salt deposits on the heat exchange tubes and the surface of the sprinklers in the cooling towers;

• The location of the reactor deep below ground level provides advantages over the conventional architecture of research reactor facilities:

most scenarios of external impact on the reactor facility are excluded, so many emergency situations resulting from explosions, tornadoes, snow load, aircraft crashes, etc. can be ignored. no need for expensive containment, the physical protection of the reactor facility is simplified;

the absence of expensive and complex systems for heat removal from the core can drastically reduce the cost of a reactor plant;

large depth of core submersion under the ground allows creating a simple and highly efficient system of natural circulation. At the same time, there are no visible restrictions on increasing the height of natural circulation and the corresponding increase in the driving pressure through the core;

the reactor can operate equally safely and efficiently in a very wide power range based on the assigned irradiation tasks;

there is practically no problem of expensive dismantling of the reactor plant;

•Automatic adjustment of the flow rate in the cooling circuits when the power level changes and the lack of an opportunity for personnel to reduce the intensity of coolant circulation eliminates emergency situations with deterioration of heat removal from the core;

• Automatic adjustment of the flow rate in the cooling circuits when the power level changes provides the utmost simplicity of reactor plant control and reduces the requirements for personnel qualification. Therefore, such a reactor can operate in countries where there are no personnel with extensive experience in managing reactor facilities, and the reactor facility can also be used for training purposes;

•Relatively low speeds of the upward flow of the coolant in the core at high pressure provide a large margin before boiling on the surface of the fuel elements and do not create problems for the upper location of the CPS elements (on the reactor head), which greatly simplifies their design;

- For the parameters of the reactor facility under consideration at a power of 25 MW, the maximum temperature subcooling on the fuel rods to the water saturation temperature in the core is 32°C in the presence of air in the heat pipe and 57°C in its absence;

- Aluminum alloys are used in fuel rods of reactor cores at temperatures not exceeding 250–270°C [9]. The range of maximum operating temperatures of fuel rods in the considered reactor facility satisfies this requirement.

- The design of the cooling circuits ensures continuous natural circulation of the coolant in the core in all modes, creating conditions for safe heat removal from fuel assemblies both during operation at power and after shutdown;

- The use of a neutron reflector external to the reactor vessel in the pool provides easy access to the irradiation volumes and the possibility of replacing irradiation devices without shutting down the reactor;

- The experience of using a heavy water reflector in a zircalium tank located in a light water pool in the Australian OPAL reactor showed the high efficiency of such a constructive solution. The deep location of the basin and the reactor pressure vessel makes it possible to organize effective cooling of the reflector’s heavy water using natural convection in the circulation pipelines and an air heat exchanger in the exhaust pipe;

- The absence of fittings and pumps in the cooling circuits ensures smooth changes in heat removal parameters and completely eliminates water hammer;

- The proposed concept of a reactor plant with shortened intra-basin circulation valves provides a quick and easy transition to core cooling with pool water, which makes it possible to carry out transport and reloading operations without problems with the reactor vessel cover open;

- The physical principles of operation of the cooling circuits are well studied and do not require additional R&D in the design of a reactor plant;

- Using three-dimensional modeling, the calculation of the main parameters of the equipment of the air cooling circuit with natural air convection, the air heat exchanger and the exhaust pipe was made. The results of a thermal-hydraulic calculation of heat transfer from the reactor core to the final recipient — atmospheric air are presented;

- The presented results of calculations according to the model in RELAP5 showed the efficiency of the cooling system using natural circulation and the achievability of a high level of thermal power of the reactor (25 MW), which corresponds to a maximum neutron flux density in the central moderating cavity above 1 × 10 15 cm -2 s -1 ;

- The presented results of calculations of emergency situations with LOCA pipeline ruptures according to the RELAP5 model show that safe heat removal from the core is ensured and there is no loss of tightness of fuel element cladding and release of the fuel composition into the coolant;

- The presented computational analysis shows that it is realistic to create a reliable functioning and completely passive system for removing heat from the core of a research reactor, which can be used as a universal cooling system for a wide range of reactor plants for various purposes.

List of sources

- R.P. Kuatbekov, V.A. Lukichev, S.V. Osipovich, S.A. Sokolov, I.T. Tretyakov, V.I. Trushkin / Research reactor for nuclear research centers, XIII Russian meeting «Safety of research nuclear installations»: abstracts. Dimitrovgrad, May 23-27, 2011 — Dimitrovgrad: JSC «SSC RIAR», 2011. — 62 p. https://refdb.ru/download/1318279.html

- Kuznetsov V.M., Khvostova M.S., Safety in nuclear research facilities, Safety in the technosphere. T. 7. No. 1. S. 57-72.

- Vitaly Uzikov, Irina Uzikova, “Universal system of passive heat removal from the core of a research reactor”, Nuclear Technology and Radiation Protection., Vol. XXXV, No. 2, June 2019

- Vitaly Uzikov, JSC “SSC RIAR”, Irina Uzikova, Assystem E&OS. Power-independent cooling system for a high-power research reactor. – Text: electronic //– URL: https://www.researchgate.net/publication/352684970_Power-independent_cooling_system_for_a_high-power_research_reactor (date of request: 24.01.2022).

- Arinkin F.M., Shaimerdenov A.A. and others / Conversion of the active zone of the research reactor VVR-K, Atomic Energy, 2017, v.123, No. 1 — p.15-20

- MCU-RFFI/A program with DLC/MCU DAT-1.0 constants library. Certification passport of the software tool No. 400 dated July 14, 2016

- Alyamovsky, A. A. SolidWorks Simulation. How to solve practical problems [Text] / — BHV-Petersburg, 2012, — 488 p.

- RELAP5/MOD3 Code Manual Volume 2: User’s Guide and Input Requirements. INEL-95/0174, NUREG/CR-5535. 1995.

- Device and method for coating fuel element cladding, patent RU2561975C1