Passive shut-off valves activated when the phase state of the flow changes

Cut-off valves of passive action are designed to shut off the flow of the medium when changing the phase state liquid-gas (steam) and gas (steam)-liquid. The valve designs are sufficiently technologically advanced and maintainable. In addition, the hydraulic resistance of such valves can be low. The advantage of the design is the absence of complex or damaged elements (for example, requiring tightness of floats). The principle of operation is very simple and the design is easy to calculate. Such valves, for example, can be used to prevent gas from the pressure compensator from entering the reactor when the primary circuit is depressurized.

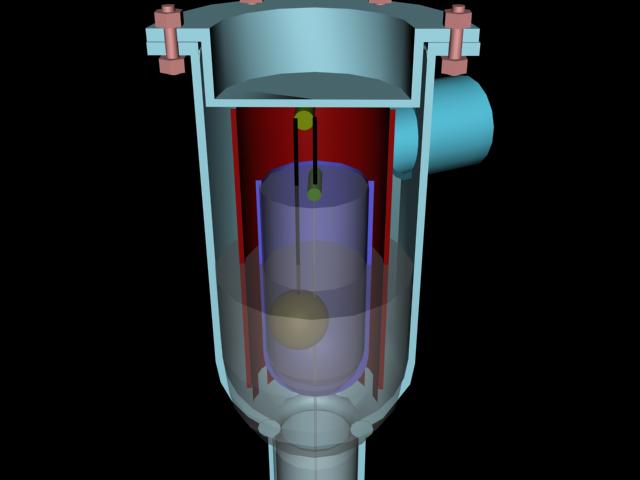

Gas (vapor) phase cut-off valve

The design of the gas (vapor) phase cut-off valve is based on a passive principle of operation and requires vertical installation with the direction of circulation of the coolant from top to bottom.

The principle of operation of a passive valve is based on a change in the total component of the force acting on the “bucket”.

• If the valve body is filled with liquid, then the balance of forces is in favor of the upper position of the «bucket», because the mass of the bucket is less than the mass of the counterweight (valve is open) M It should be noted that the opening in the upper part of the shell (flow divider) must be small so that the corresponding flow rate does not create a significant pressure drop across the «bucket»

Mwithout weight >Membosity

• If gas begins to flow into the annular space and further down, the gravity force of the liquid contained in it (and above it) begins to act on the “bucket”, so the balance of forces shifts towards lowering the “bucket” and closing the valve.

(Mwithout weight <Membosity + Mvody)

• When the volume of the valve and the circulation circuit is refilled with liquid, the balance of forces that opens the valve is restored.

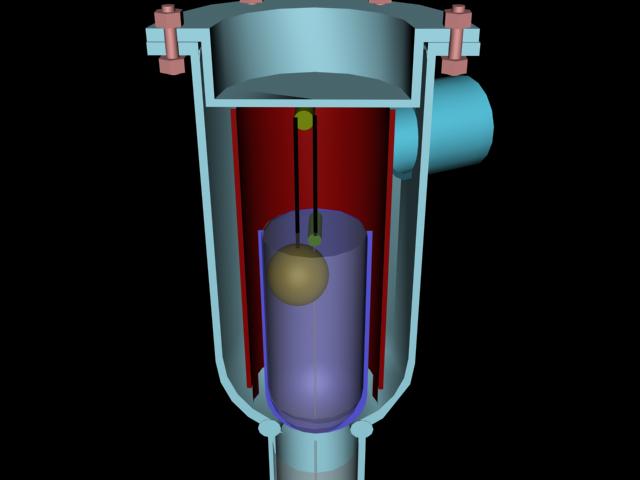

Liquid cut-off valve

The design of the gas (vapor) phase cut-off valve is based on a passive principle of operation and requires vertical installation with the direction of circulation of the coolant from the bottom up.

The operating principle of the passive valve is based on a change in the total component of the force acting on the “bell”.

- If the valve body is filled with gas, then the balance of forces is in favor of the lower (open) position of the shut-off element (“bell”), since its mass is greater than the mass of the counterweight. It should be noted that the “bell” and the counterweight are located in a casing, which practically excludes the dynamic impact on them from the side of the moving stream.

Magainst the weight <Mbell

- When the valve body is filled with liquid, a gas (vapor) cavity is formed in the “bell”, which shifts the balance of forces towards lifting and closing the valve.

Magainst the weight > Mbell – Mdisplaced liquid = Mbell – (Vdisplaced liquid × ρ liquid)

A guide (such as a pipe) can be provided to prevent the lines from twisting when the counterweight is moved.

uzikof@gmail.com

uzikov62@mail.ru

Address

Bratskaya st., 27 apt. 61 Dimitrovgrad, Ulyanovsk region, Russia, 433515

Call Us

+7 917 622 40 47